YOU CAN COUNT ON OUR EXPERTISE

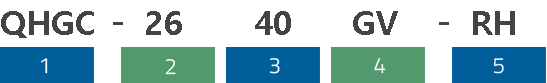

| Model No. | Type | Clamping Force(kgf) @70kgf/㎠ |

Piston Diameter(ø) |

Effective Area(㎠) |

Stroke(mm) | Oil Capacity(㎤) | Operating Pressure Range (kgf/㎠) |

Operating Temperature Range(℃) |

Weight (kg) |

||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Total | Extra | Clamp(Push) | Unclamp(Pull) | ||||||||

| QHGC-2436G | G | 240 | 24 | 4.5 | 18.5 | 2.5 | 7.2 | 5.9 | 15~70 | 0~60 | 0.5 |

| GV | 0.51 | ||||||||||

| QHGC-2640G | G | 297 | 26 | 5.3 | 20.5 | 3 | 10.9 | 8.6 | 0.6 | ||

| GV | 0.61 | ||||||||||

| QHGC-3048G | G | 391 | 30 | 7.1 | 23.5 | 3 | 16.6 | 13.0 | 0.9 | ||

| GV | 0.91 | ||||||||||

| QHGC-3555G | G | 487 | 35 | 9.6 | 26 | 3 | 25.0 | 19.8 | 1.2 | ||

| GV | 1.21 | ||||||||||

| QHGC-4565 | G | 852 | 45 | 15.9 | 29.5 | 3 | 46.9 | 37.7 | 2.0 | ||

| GV | 2.01 | ||||||||||

| QHGC-5575G | G | 1,037 | 55 | 23.8 | 35 | 3 | 83.2 | 69.9 | 3.0 | ||

| GV | 3.01 | ||||||||||